The IXDL zoning advantage

Incorporating multiple fans within each unit, IXDL allows you to set different temperatures for different rooms within the same building simultaneously. Our IXDL system’s individual zoning capacity enables you to find the perfect balance between energy savings and comfort levels.

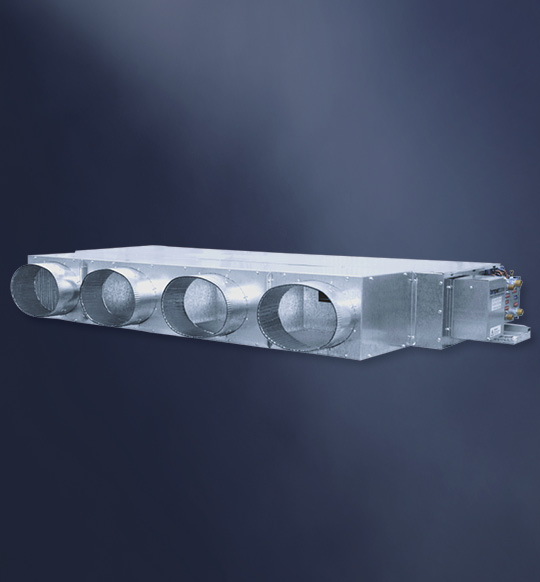

IXDL Low profile CHW FCU's

Available in:

- 3 Row Cooling

- 3 Row Cooling + 1 Row Heating

- 4 Row Cooling

- 4 Row Cooling + 1 Row Heating

Airflow Range (l/s):

200, 400, 600, 800, 1000

Designed to Impress

The stepless modulation capability of EC fan speeds make it possible to accurately regulate air volume in strict relation to a room’s real air conditioning requirements.

This also enables temperature and humidity fluctuations to be significantly minimised, leading to superior comfort levels.

3RD PARTY

Can be controlled by a third party device

EC FAN

Variable fan speed control 0-10VDC input

SHOPPING CENTRES

Perfect for shopping centre applications

WIDE ESP

Wide ESP range

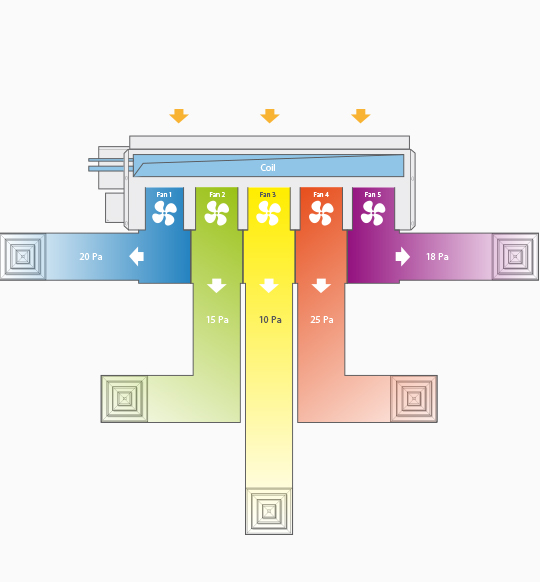

Multi Airflow

Temperzone IXDL-Y Multizone units offer an added level of control with zone dedicated EC motor fans for up to 5 zones. EC fan motors can be controlled to deliver the required airflow at the required pressure to each duct.

Each fan can be controlled via an external signal to supply the airflow to match the cooling/heating load within the occupied space. Matching airflow to the cooling/heating load reduces the need to modulate the chilled water / heating water valve, thereby reducing pump energy requirements.

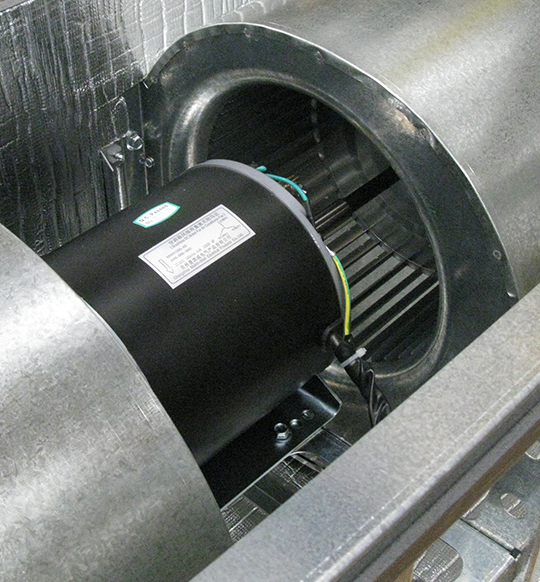

EC Fan

EC technology motors provide higher efficiency and energy savings compared with AC motors.

EC stands for Electronically Commutated, often referred to as a Brushless DC electric motor (BLDC motor) with integrated controller electronics. The fan is able to be speed controlled by 0-10VDC or as a fixed amount of speeds selectable on the unit.

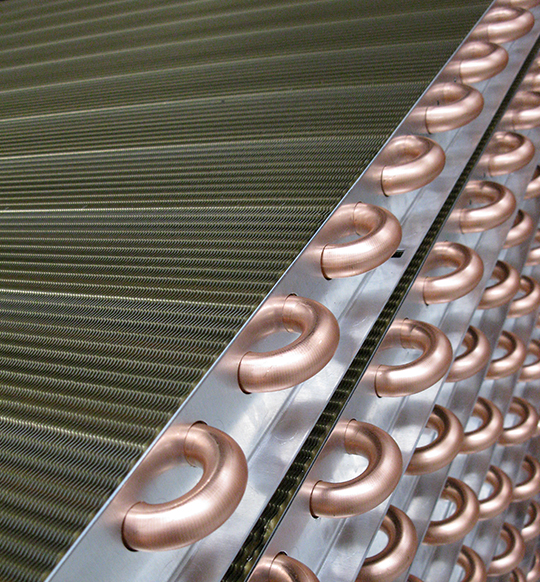

Epoxy Coated coils

All Temperzone units come standard with epoxy coated indoor and outdoor coils for added protection in harsh enviroments.

For corrosive environments, varieties of lacquered fin stock have been developed as an alternative to the more expensive copper fin stock.

Of the various coatings, for aluminium fin stock, epoxy has emerged as the preferred coating as protection against both chemical and salt laden air corrosion. The controlled application of epoxy, to the aluminium fin stock, results in a highly corrosion resistant epoxy film of only 4-5 microns.