MAGNUS Inverter In-line Underfloor.

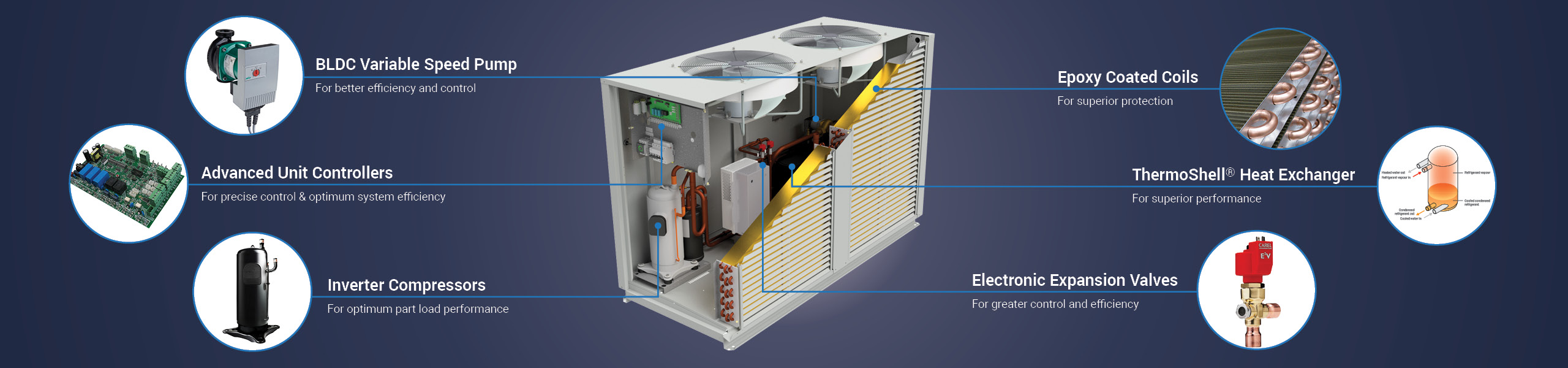

MAGNUS Underfloor In-line inverter systems remove the requirement for a buffer tank, significantly increasing the efficiency and cost effectiveness of the overall system. They combine variable capacity BLDC pump and inverter compressor technologies to efficiently maintain a constant supply water temperature under the widest possible range of ambient conditions. They are particularly well suited where Temperature zoning is required.

MAGNUS MWU

Capacity Range (heating):

- MWU 180 16.1kW (Range: 3.7kW ~ 20.0kW)

- MWU 250 20.4kW (Range: 4.6kW ~ 25.5kW)

- MWU 450 37.5kW (Range: 8.5kW ~ 46.5kW)

- MWU 900 74.0kW (Range: 9.0kW ~ 86.0kW)

Refrigerant:

R410A

Inverter In-line Design

- No need for buffer storage tanks

- Reduction in required pump power

- Reduction in piping required

- Most energy efficient system

- Reliable long life system

- Low service / maintenance requirements

- Compact Design

MAGNUS Inverter Inline Design

MAGNUS In-line systems take full advantage of inverter compressor technology which increase in efficiency at part load operation. MAGNUS Inverter heat pumps supply heated water at a constant required temperature while variable speed BLDC pumps control delivered capacity. This in-line design means there is no requirement for a buffer tank. The inverter compressor, as the load is met, significantly reduces energy consumption by turning itself down to operate at part load while still maintaining the heating requirements of the application.

Inefficient Conventional Systems

A conventional heat pump, typically operates at high speed turning itself on and off as the buffer tank requires heating. This method is inefficient as the buffer tank must be continually overheated beyond the demand setpoint due to the cooled return water mixing with heated water in the buffer tank.

Designed for Efficiency

MAGNUS in-line inverter systems achieve at least 30% reductions in total system power input. MAGNUS inverter compressor, as the load is met, significantly reduces energy consumption by turning itself down to operate at part load. A conventional heat pump, typically operates at high speed turning itself on and off as the buffer tank requires heating. This method is inefficient as the buffer tank must be continually overheated beyond the demand setpoint.

Lower Capital Investment

MAGNUS In-line systems directly provide the capacity required for the application eliminating the need for buffer tanks and primary / secondary circuits. This approach reduces installed system capital costs, and significantly increases system efficiency, especially under part-load conditions, resulting in one of the most cost-effective water heating systems on the market.

- No need for buffer storage tanks

- Reduction in required pump power

- Reduction in piping required

- Low service / maintenance requirements

- Most energy efficient system

Designed to Operate Reliably, Longer

MAGNUS In-line systems are low maintenance, with low service requirements. Its ThermoShell® heat exchanger, unlike traditional heat exchangers, are fouling resistant. Also, the advanced unit controller combined with application specific design uniquely enables the compressor to constantly operate within its design limits improving unit life.