Integrated Restaurant Solution Case Study

Integrated Hot Water / Fresh Air Tempering / Heat Pump Water Heater system

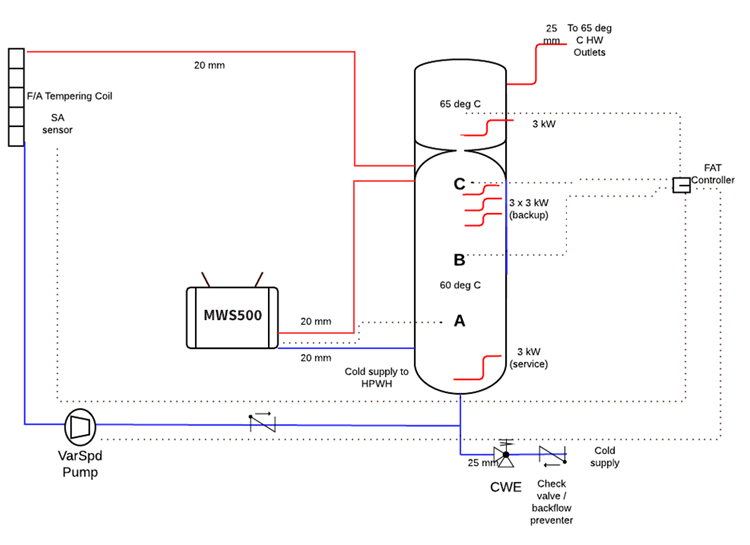

An integrated hot water and fresh air tempering system powered by a MAGNUS MWS single pass heat-pump water heater was installed at KFC Rolleston, New Zealand.

This case study provides an assessment of the performance of the system for 12 months. The system achieved an annual reduction in electricity usage of 72.6 MWh when compared with a conventional electric resistance-based system, an estimated savings of $10,900. The HPWH achieved an annual COP of 3.4, corresponding to a reduction in electricity usage of 68%. The system reduced the contribution of water heating and fresh air tempering to the total store electricity consumption from 23% to 8%.

Background

An integrated water and fresh air tempering system was installed at the Rolleston store. The system combines a MAGNUS 50kW single pass heat-pump water heater (HPWH) with a 500 L thermally zoned storage tank. Also connected to the system is a 31.5kW fresh air tempering (FAT) coil, embedded in the supply air duct.

Integrating the potable (tap) water heating with the FAT system allows the capital cost of the HPWH to be spread over two significant energy loads, and utilising the spare capacity of the water heater. A zoned hot water storage tank was incorporated into the design to ensure the priority for hot water at the tap was maintained.

The system is monitored using a Splash monitoring system, to determine an energy balance of the water heating system. From this energy balance, the water and FAT energy demands can be separated.

Power and monitoring equipment has also been installed, which measures the total electricity demand of the store, and separately, the electricity consumption of the water heating system. This enables the calculation of the energy savings delivered by the heat-pump water heater as referenced against an all electric system, as well as a proportion of the total store electricity use.

The traditional installation this system replaces is an 18kW electric storage water heater tank, and a 31.5kW electric duct heater, operating in three stages. A store in Glenn Innes, Auckland was initially monitored, which provided hot water and fresh air tempering usage data as a daily as well as a seasonal profile. This data was used to determine the likely energy usage, and therefore electricity savings at the Rolleston store.

System Design

There are several design constraints factored into this system. These are:

-

Kitchen hot water is required at a minimum of 65˚C at the tap.

-

Washroom hot water is tempered to 55˚C.

-

Hot water is mostly used in the kitchen to defrost chicken in large sinks. Each defrost requires approximately 300 L of hot water within 10 minutes. Defrost events are periodic during the day, based on how busy the store is.

-

There is minimal hot water usage during much of the day, other than for defrosting chicken.

-

Significant quantities of hot water is also used in the late evening for store washdown.

-

The hot water production of the HPWH decreases with decreasing ambient temperatures.

-

The FAT energy demand increases with decreasing ambient temperatures.

To meet the simultaneous hot water demand and FAT demand under design conditions (1˚C) ambient temperatures would have required either a substantially larger storage tank, or a doubling in the capacity of the HPWH. Both of these options would have significantly increased the capital cost of the system. An alternative approach has been used instead, using a zoned hot water storage tank in conjunction with a single pass HPWH.

.jpg)

Figure 1: Schematic of integrated HW/FAT/HPWH system

Features of the system include

-

The HPWH (MWS500) produces 62˚C water in a “single pass” through the system. This water is drawn from the bottom of the tank, and is added to the top of the lower tank. The “real time” production from the MWS500 is available for “real time” hot water usage.

-

The upper tank (40 L) allows for water preheated to 62˚C to be heated to 65 – 68˚C to meet Building Code requirements for kitchen hot water. The upper tank can provide a continuous supply of 65˚C hot water at an unmixed rate of 7 L/min.

-

The FAT coil takes 60˚C water from the top of the lower tank, and tempers the incoming air to 18˚C. A variable speed controlled pump maintains the FAT to 18˚C.

-

Three temperature sensors allow for the tank to be Zoned, based on the amount of hot water remaining in the tank.

-

Zone A: The HPWH begins a reheat cycle. There is full FAT service.

-

Zone B: The variable speed pump reduces in speed to minimum to restrict FAT service. The FAT supply air temperature reduces from 18˚C to approximately 13˚C

-

Zone C: FAT service is temporarily halted, with all remaining hot water prioritised to the kitchen taps.

-

-

The FAT Controller maintains the FAT Supply Air temperature to 18˚C, maintains the upper tank temperature to 65-68˚C, and provides freeze protection of the FAT coil.

System Performance

The energy performance of the system has been determined for a 12 period through the Splash Monitoring system. The monitoring system installed included the following:

-

Flow meter on the total hot water usage

-

Flow meter on the HPWH (total HW generated)

-

Temperature sensors on HPWH flow / return, and at each zone in the tank

-

Current transducers on the HPWH, and each electric element in the tank.

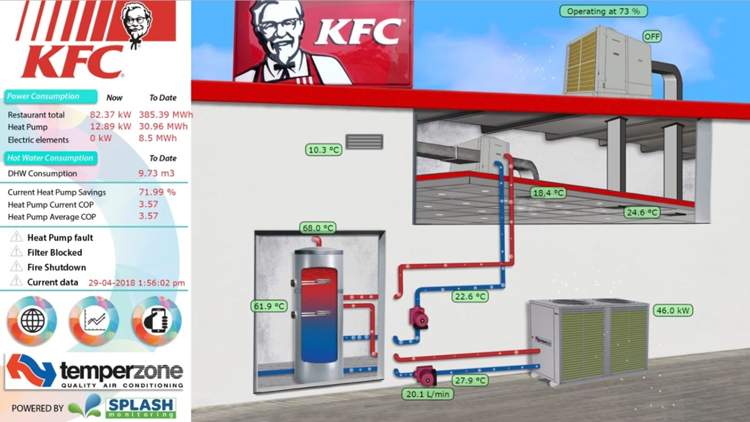

An animation was developed for this project on the Splash Monitoring platform showing how the system is operating in real time (updated at 30 second intervals.).

.jpg)

Figure 2: Live view animation of KFC Rolleston system

The system performance data was downloaded from the Splash Monitoring system in 30 second intervals, and analysed.

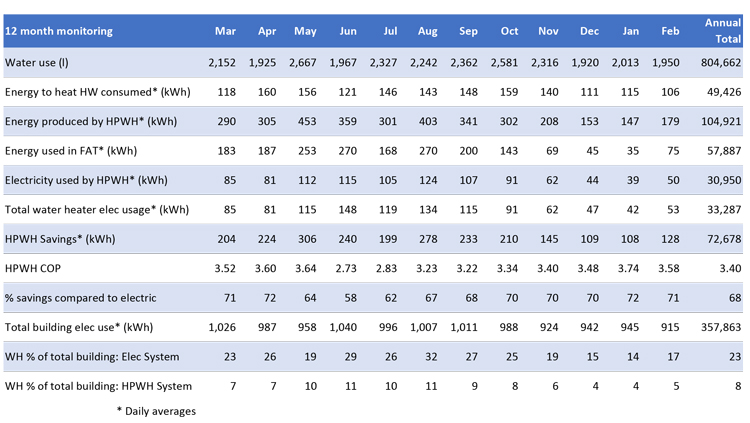

The key performance data of the integrated system during the monitored period is shown in Table 1.

.jpg)

Table 1: Key performance data during the monitoring period.

The average daily hot water consumption of the store was 2200 L and heating this water required 49.4 MWh of energy. The FAT system consumed 57.9 MWh of heated water, resulting in a total water heating energy requirement of 107 MWh. This water was heated using 31 MWh of electricity through the HPWH, and a further 2.33 MWh of electric resistance heating. The HPWH achieved an annual COP of 3.4, and a 68% reduction in electricity consumption compared to an all-electric system. This corresponds to a 72.6 MWh reduction in electricity usage, at a value of $10,900 (at 0.15c/kWh). As proportion of total electricity usage, an all-electric water heating and FAT system would be expected to account for 23% of the total electricity usage of the store. The integrated HPWH based system has reduced that to 8%.

On-going optimisation of the system occurred during the first half of winter, and this resulted in larger ongoing energy savings achieved by the system.

Assessment of the System Design

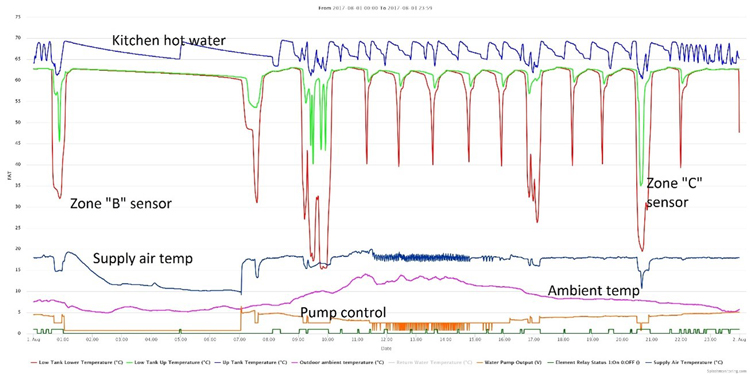

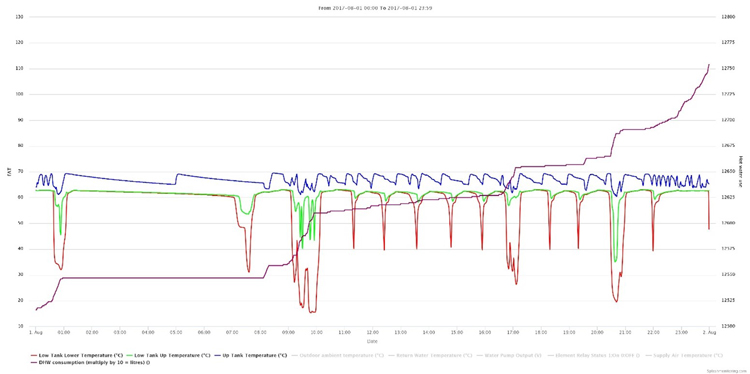

This project demonstrates an integrated hot water and FAT system, using a zoned tank. How this system works in practice is illustrated by considering a snapshot of the monitored data on 1 August. The kitchen taps are supplied with a hot water at the required temperature almost the entire time. It is important to note that the temperatures shown are those at the location of the sensor, not the temperature actually being delivered by the system. The delivered water temperatures will always be hotter than at the sensor, which is lower in the tank than the outlet from the tank.

The Zone B sensor is approximately midpoint up the lower tank. During periods of large hot water demand, the lower half of the tank is depleted of hot water. During these periods, the FAT pump reduces to minimum speed, and the FAT supply air temperature is reduced temporarily from 18˚C to 15˚C. At 20.39, the combination of hot water draw-off, and a high FAT energy demand led to a 2 minute pausing of FAT whilst the system recovered. The single pass water heater allowed the system to recover to normal operation within 20 minutes.

.jpg)

Figure 3: FAT / tank zoning monitored data.

.jpg)

Figure 4: HW demand overlain on tank sensor temperatures

Conclusion

This is the first system to integrate potable water heating and fresh air tempering using heat-pump water heaters in New Zealand.

The zoned tank system provides a good compromise between capital cost, maintenance of kitchen hot water, and very limited restrictions in FAT service.

The system resulted in a reduction in electricity usage of 72.6 MWh, at an estimated savings of $10,900. The energy savings is the equivalent of the electricity required to operate 23 electric vehicles with a daily commute of 50 km, 365 days a year.

This system is now being installed across the Restaurants Brands portfolio in NZ, including KFC and Taco Bell branches. This includes the installation of R32 MAGNUS MWS units as a low GWP solution.

Photos

.jpg)

Fresh Air Tempering coil at Rolleston

.jpg)

MAGNUS MWS500 single-pass heat pump at Rolleston KFC

.jpg)

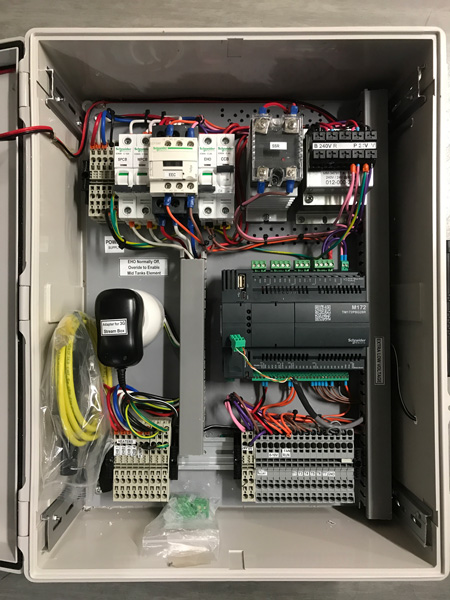

FAT controls / monitoring system / automatic backup at KFC

.jpg)

Zoned storage tank at KFC

.jpg)

Inverter OPA Rooftop Packaged units for main space heating and cooling